Revolutionizing Packaging: The Power of Flowpack Machines

Why Packaging Matters More Than You Think

Ever wondered why the same biscuit stays fresh for weeks in one store but turns stale quickly in another? Or why some snacks look irresistibly fresh while others seem dull? The answer lies in flowpack technology, the backbone of modern packaging solutions.

At its core, a horizontal flowpack machine does more than just wrap products—it preserves freshness, ensures hygiene, and enhances shelf appeal, all while reducing costs and increasing production efficiency.

Imagine this:

✅ A freshly baked croissant is swiftly wrapped in protective film, locking in its flaky texture.

✅ A chocolate bar, perfectly sealed, preventing melting or contamination.

✅ A crispy wafer that stays crunchy for months, thanks to airtight packaging.

This is the power of the horizontal flowwrapper machines.

Explore our range of horizontal flowpack packaging machines today and discover how they can revolutionize your packaging operations!

Horizontal Flowpack Packaging Machines: Efficient & Versatile Packaging Solutions

What Are Horizontal Flowpack Packaging Machines?

Horizontal flowpack packaging machines are versatile and efficient solutions for packaging a wide variety of products. These machines are designed to wrap items in protective, visually appealing, and market-friendly packaging. From food items like cakes, cookies, biscuits, chocolate bars, rice cakes, tortilla bread and sliced bread to non-food items like soap, razors and sponges, flowpack machines provide seamless packaging solutions for diverse industries.

Horizontal Flowpack Machines (HFFS – Horizontal Form Fill Seal) are widely used in the food and non-food industries to package products efficiently, ensuring protection, freshness, and extended shelf life. These machines wrap products in a continuous film, forming a hermetically sealed package that enhances product safety and visual appeal.

Our advanced flowpack machines are designed to handle a variety of product shapes and sizes, ensuring high-speed, precise, and cost-effective packaging for industries requiring efficiency, flexibility, and reliability.

Operation System of Flowpack Machines

Horizontal flowpack packaging machines operate with a simple yet advanced mechanism:

✅ Product Feeding: Products are placed onto a conveyor system manually or automatically from the production line.

✅ Film Wrapping: A continuous film roll wraps the product, forming a protective layer around it.

✅ Sealing and Cutting: The machine seals the film using heat and pressure, and then cuts it to form individual packages. Depending on the system, the sealing can be executed using rotary or box-motion jaws.

Types of Horizontal Flowpack Packaging Machines

Horizontal flowpack machines can be categorized based on their jaw systems and functionalities:

1. Rotary Jaw System Flowpack Machines

✅ Ideal for high-speed packaging of small to medium-sized products.

✅ Uses continuously rotating sealing jaws for fast and efficient sealing.

✅ Best for snack bars, biscuits, cookies, chocolates, and bakery items.

2. Box Motion System Flowpack Machines

✅ Uses a straight, back-and-forth (box motion) sealing movement.

✅ Ensures stronger, airtight seals, ideal for modified atmosphere packaging (MAP).

✅ Best for meat, cheese, fresh bakery products, and perishable items.

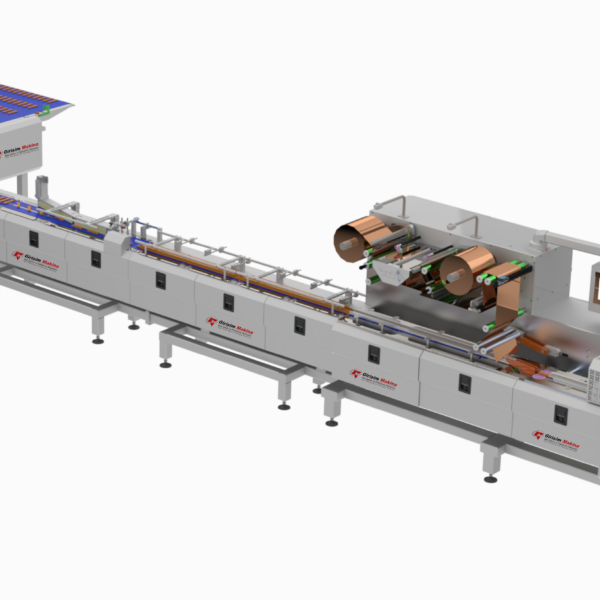

3. High-Speed Flowpack Machines with Automatic Product Feeding Applications

✅ Designed for large-scale production lines, reaching speeds of hundreds of packs per minute.

✅ Equipped with advanced automation, servo-controlled systems, and intelligent sensors.

✅ Best for mass production of confectionery, bakery, and pharmaceutical products.

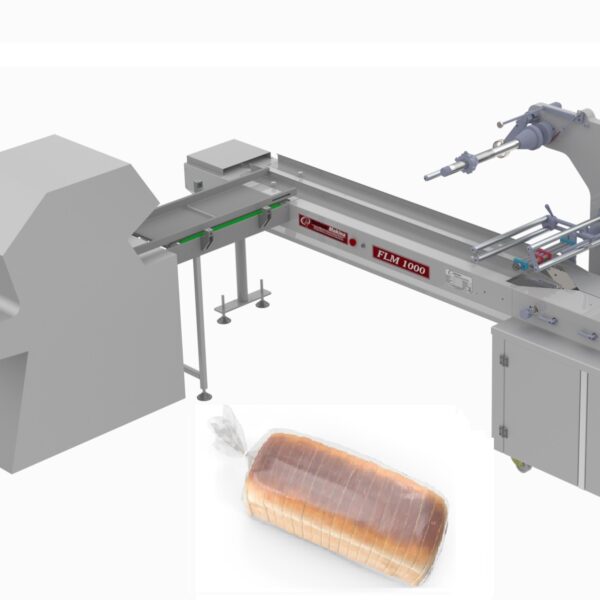

4. Specially-Designed Flowpack Machines

✅ Customized for unique product requirements, such as fragile, irregular, or multi-pack items.

✅ Can integrate with weighing, labeling, and cartoning systems.

✅ Best for frozen foods, croissants, tortilla breads, multiple buns, rice cakes, sliced bread, medical supplies, and hardware products.

Where Are Flowpack Machines Used?

Flowpack packaging is essential across various industries:

✅ Bakery & Confectionery – Cake packaging, biscuit packaging, wafers packaging, cookies packaging, croissants packaging, chocolate packaging, couverture packaging, halvah packaging, muffin cakes packaging, swiss rolls cake packaging, baguettes packaging, pita bread packaging, tortilla wraps packaging, burger buns packaging, sandwich rolls packaging, layered cakes packaging, sponge cakes packaging, sliced bread packaging and many others…

✅ Snacks & Energy Bars – Cereal bars, protein bars, granola bars, rice cakes, corn cakes and similar other ones

✅ Meat, Dairy & Frozen Foods – Cheese, sausages, processed meats, frozen snacks, frozen baker and similar other ones.

✅ Fruits & Vegetables – Fresh produce packaging, greens packaging, pre-cut fruit packaging, salad mixes packaging, apples packaging, pears packaging, bananas packaging, cucumbers packaging, tomatoes packaging, bell peppers packaging, carrots packaging, cherry tomatoes packaging and many others…

✅ Non-Food Products – Soap packaging, toothbrush packaging, cutlery set packaging, sponges packaging, medical masks packaging, gloves packaging, disposable razor packaging, cleaning towels packaging, electrical components packaging, hardware items packaging and many others...

With the ability to adapt to different product shapes and sizes, flowpack machines are among the most versatile and widely used packaging solutions in the world.

Benefits of Flowpack Machines

✅ High-Speed & Efficiency – Automates packaging to increase production output and reduce labor costs.

✅ Extended Shelf Life – Airtight sealing provides protection against moisture, oxygen, and contamination.

✅ Attractive & Secure Packaging – Enhances brand presentation and prevents tampering.

✅ Cost-Effective & Material Efficient – Uses minimal packaging material, reducing waste and costs.

✅ Versatility in Packaging – Can package single items, multipacks, and irregular-shaped products.

✅ Material Compatibility: Works with various packaging films, including polypropylene, laminated films, and biodegradable materials.

✅ Sealing Options: Cold Sealing and Heat-sealing for durable and secure packages.

✅ Adjustable Settings: Easily adaptable to accommodate different product sizes and shapes.

✅ User-Friendly Interface: Advanced touchscreen controls for monitoring and adjusting operations.

✅ Seamless Integration – Can be connected to self-adhesive labeling machines, coding units, weighing and labeling machines, carton packaging systems, metal detectors, automatic clipping machines for a fully automated workflow.

✅ Enhanced Product Presentation: Flowpack machines create sleek, attractive packaging that enhances product visibility and appeal on market shelves.

✅ Modified Atmosphere Packaging (MAP): Specific flowpack machines support MAP technology, which replaces the air inside the package with a gas mixture to preserve freshness and extend the shelf life of perishable goods.

The Future of Flowpack Packaging

With increasing demand for sustainable, smart, and efficient packaging, the flowpack industry is evolving:

✅ Eco-Friendly Packaging – Machines are now compatible with biodegradable and recyclable films.

✅ Advanced Automation – AI-powered flowpack machines improve precision, reduce waste, and enhance efficiency.

✅ Smart Packaging & Traceability – Integration with QR codes, RFID, and digital printing for better supply chain tracking.

As consumer preferences shift toward sustainable, tamper-proof, and visually appealing packaging, flowpack machines remain at the forefront of modern packaging solutions.

The future is clear: Businesses that invest in cutting-edge flowpack solutions gain a decisive market advantage.

Why Choose Our Flowpack Machines?

With 30 years of expertise since 1995 in the packaging industry, our company delivers:

✅ Industry-Leading Technology – High-speed, energy-efficient, and smart-controlled packaging machines.

✅ Customizable Solutions – Tailored to meet the unique requirements of your production line.

✅ Reliable & Durable Machinery – Built with high-quality materials for long-lasting performance.

✅ Comprehensive Support – From installation to after-sales service, we provide end-to-end support.

✅ Global Reach – Trusted by food manufacturers worldwide for our cutting-edge flowpack packaging solutions.

Upgrade Your Packaging with the Best Flowpack Machines!

Contact us today to find the right flowpack solution for your business and take your production to the next level.